How Do I Form This Part?

How Do I Form this Part

Assessing Your Part + Choosing Your Process

In our previous posts about part forming, we looked at an aluminum frame section from the aerospace industry and an aluminum medical tray used in the medical field. To choose the right forming process for these parts, we looked at four areas: order size and shape, product finish, material and secondary processes. We found that fluid-cell forming would be a good fit for the frame section, while hydroforming would be the right process for the medical tray.

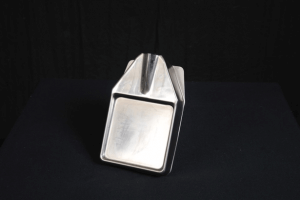

Today, we’ll be considering a part from the food service equipment industry. This stainless steel part was designed for a commercial juice machine. To determine the best method for forming this part, let’s start with order size and shape.

At Jones Metal Products, we offer many in-house capabilities, which make both small and large orders cost effective. The next factor to consider is the product’s shape. For a complex shape like this juice machine part, a process like hydroforming would be more efficient and cost effective than stamping, which would require the creation of more expensive metal dies.

The next consideration is the final finish on the product. Is your product going to be seen in its final application or need a smooth finish to work properly? This juice machine part has many flat surfaces that need to have a polished look at the end of production. In this case, it’s more effective to use a fluid based process, like hydroforming. This gives a cleaner finish on the first round of forming, and downstream finishing processes aren’t as necessary.

After finish, you should consider the material you’ll need for your part. As we said, hydroforming would be a good option for this juice machine part. JMP can accommodate a wide range of metals for hydroforming, and stainless steel is a viable metal for this process.

The final step on the checklist is choosing the downstream processes you might need after initial forming. For some parts, like our juice machine part, further processing may not be needed. Nevertheless, JMP can provide machining, lasering, powder coating or heat treating services to your products.

For a complexly shaped, smooth finish, stainless steel part like this one, hydroforming would be an excellent fit. If you would like more information about hydroforming, or the JMP process that will meet your product need, contact us or call 888-479-9566.